Table of Contents

In the powerful universe of assembling and item plan, the decision of embellishment methods can fundamentally affect the quality, solidness, and execution of the end result. Two well known strategies that stand apart are 2k molding vs Overmolding. Every strategy enjoys its interesting benefits and applications, making them fundamental devices for enterprises like clinical, electronic, home devices, carrier, and car. HITOP, a forerunner in making sturdy and superior execution molds, succeeds in both 2k molding and overmolding, offering customized administration to meet the particular requirements of their clients. In this blog entry, we will investigate the distinctions between 2k molding and overmolding, their advantages, and how HITOP’s mastery can upgrade your assembling processes.

Grasping 2k molding

What is 2k molding ?

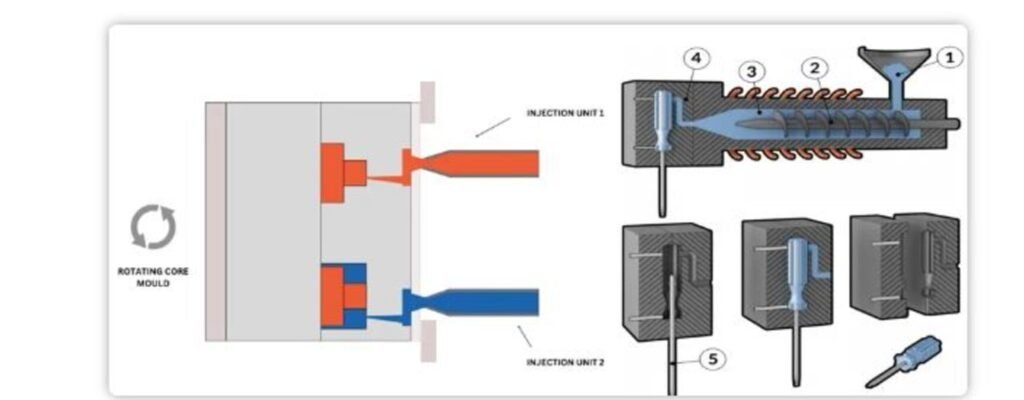

2k molding , otherwise called two-shot trim or double shot trim, is an interaction that includes infusing two unique materials into a solitary form during one creation cycle. This procedure takes into consideration the making of complex, multi-material parts with differed properties and functionalities. The materials can vary in variety, hardness, or type, like consolidating plastic with elastic.

Benefits of 2k molding

- Improved Plan Adaptability: 2K trim empowers the combination of different materials into a solitary part, offering more noteworthy plan adaptability and the capacity to make complex shapes and designs.

- Further developed Item Quality: By consolidating various materials, 2k molding can upgrade the usefulness and execution of the item, like further developing hold, protection, or tasteful allure.

- Cost Proficiency: Since 2k molding includes a solitary creation cycle, it tends to be more practical contrasted with conventional multi-step processes. This lessens fabricating time and work costs.

- Solidness: The cycle major areas of strength for guarantees between the two materials, bringing about tough and hearty parts that can endure different burdens and natural circumstances.

Uses of 2k molding

2k molding is broadly utilized in different businesses to create great and dependable parts. A few normal applications include:

- Clinical Gadgets: Creating ergonomic and biocompatible parts for clinical instruments and gadgets.

- Hardware: Assembling parts with coordinated seals or gaskets to safeguard against dampness and residue.

- Car: Making complex inside and outside parts that require different material properties for usefulness and style.

- Domestic devices: Delivering strong and easy to use parts, like handles and fastens, with further developed hold and usefulness.

Figuring out Overmolding

What is Overmolding?

Overmolding is a cycle where one material is formed over another material or substrate. This strategy includes forming an extra layer of material onto a current part, which can be produced using an alternate material. Overmolding can upgrade the exhibition, usefulness, and style of the base part.

Benefits of Overmolding

- Upgraded Ergonomics: Overmolding can add delicate touch surfaces to items, working on their ergonomics and client solace.

- Further developed Usefulness: By adding layers with explicit properties, overmolding can improve the usefulness of parts, for example, adding non-slip surfaces or defensive coatings.

- Tasteful Allure: Overmolding considers the making of outwardly engaging parts with multicolor and multi-material plans.

- Cost Reserve funds: Overmolding can diminish gathering costs by wiping out the requirement for discrete parts and get together advances.

Uses of Overmolding

Overmolding is utilized in many ventures to work on the presentation and presence of different items. A few normal applications include:

- Clinical Gadgets: Improving the hold and solace of clinical instruments and apparatuses.

- Hardware: Adding defensive layers to electronic lodgings to further develop solidness and protection from natural variables.

- Car: Making parts with incorporated seals and gaskets for further developed execution and life span.

- Domestic devices: Delivering leaves behind superior grasp, like handles and handles, for better client experience.

HITOP’s Skill in 2K Trim and Overmolding

Obligation to Quality and Solidness

HITOP is eminent for its mastery in making tough and superior execution molds. Their obligation to quality guarantees that each part delivered utilizing 2k molding or overmolding satisfies the most noteworthy guidelines of strength and execution. HITOP’s high level assembling procedures and thorough quality control processes ensure the development of dependable and enduring parts.

Customized Administration and Modified Arrangements

Understanding that every client has remarkable necessities, HITOP offers customized administration and redid arrangements. Their group of experienced engineers works intimately with clients to plan and foster forms that address explicit issues and details. Whether it’s for the clinical, electronic, home devices, aircraft, or auto industry, HITOP tailors their administrations to convey ideal outcomes.

Mechanical Progressions

HITOP stays at the front line of mechanical progressions in the assembling business. By putting resources into cutting edge gear and constant innovative work, HITOP guarantees that their clients benefit from the most recent advancements in 2K trim and overmolding. This obligation to innovative greatness permits HITOP to deliver excellent parts with unrivaled execution and accuracy.

Extensive variety of Utilizations

HITOP’s skill in 2k molding and overmolding covers a great many applications across different businesses. Their capacity to deliver complex, multi-material parts with improved usefulness and style makes them a favored accomplice for organizations looking for first class fabricating arrangements.

Picking HITOP for Prevalent Assembling Arrangements

In the cutthroat scene of assembling and item plan, the decision of embellishment procedures can have a huge effect in the quality and execution of the eventual outcome. 2k molding and overmolding are two imaginative strategies that offer various benefits, from upgraded plan adaptability and further developed item quality to cost effectiveness and sturdiness.

HITOP stands apart as a forerunner in the business, offering uncommon skill in both 2K trim and overmolding. Their obligation to quality, customized administration, and mechanical progressions makes them a solid accomplice for organizations in the clinical, electronic, home devices, carrier, and auto ventures. By picking HITOP, you can guarantee that your items are made to the best expectations, with sturdy and superior execution forms that meet your particular necessities.

Contact HITOP today to become familiar with their 2k molding and overmolding arrangements and how they can assist with hoisting your assembling cycles and item plan. With HITOP, you can accomplish unrivaled outcomes and gain an upper hand in your industry.

YOU MAY ALSO READ

You may also read the latest articles on our website (apaxnews.com) to stay updated.